Galvanized Steel Strip Locked Roof Sheet Metal Forming Equipment CE / SONCAP

Published date: July 20, 2017

Nigeria, Hangzhou, Xiaoshan

Metalrollformer@yahoo.com

Views: 961

Check with seller

008615868142550

Description

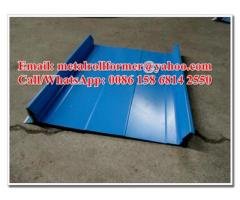

Pre-painted and Galvanized Steel Modern Strip Selflocked Roof Panels Making Machine with Automatic Hydraulic Decoiler

Introduction

The advertised metal roll forming machine here is an advanced metal rollformer, which is manufacturing prepainted and galvanised modern striplocked roof sheets with a high quality. We are also supplying all kinds of metal roll forming machine with high quality, such as trapezoid /wave profile roof & wall panel roll forming machine, steel C & Z purlin roll forming machine, step roofing tile roll forming machine, floor deck roll forming machine, C stud & U track roll forming machine, roller shutter door slat roll forming machine, highway guardrail roll forming machine, ridge cap roll forming machine, roof rain gutter roll forming machine, water downspout roll forming machine and so on.

Main Components of Steel & Aluminium Selflock Roofing Panel Rollforming Machine

1 Coil Decoiler 1 set

2 Roll Former Machine

Direction Guilder 1 set

Rolling System 1 set

Post-cutting Device 1 set

3 Supporting Tables for Finished Products 2 sets

4 Hydraulic Station for Cutting Device 1 set

5 PLC Control Cabinet 1 set

6 Tools Box with Spare Parts 1 set

Technical Parameters (some parameters depend on the final design)

1 Machine name: strip self lock roof sheets forming machine

2 Machine dimension (mm) 7000*1200*1500; Total weight (Kg): 7000

3 Forming steps: 18; Forming speed (m/min): 15-20

4 Main driving motor power(Kw) : 5.5

5 Diameter of rolling shaft (mm) 72; Hydraulic pressure(MPa) 10

6 Power for hydraulic decoiler(Kw) 5.5 x 2; Decoiler max capacity (Kgs) 5000

7 Control system: Mitsubishi PLC; Electric condition 380V/3Phase/ 50HZ

8 Raw material thickness (mm): 0.3-0.7

Working Flow

Uncoiling--->Sheet Guilding--->Rolling--->Cutting--->Finished Roof Panels on Runout Tables

Applications:

An accomplished contractor can install these strips striplocked roof sheets quickly. If the roof is stripped off and a storm is on the way, shortening the process by a day or two may prove to be a critical advantage. Because of the material’s light weight, customers can save on engineering and building the supporting structure.

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet making machine, normal steptile roof sheet making machine, metcopo step tile roof sheet making machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Galvanized Steel Strip Locked Roof Sheet Metal Forming Equipment CE / SONCAP, please contact us by the following information!

Email: metalrollformer@yahoo.com

Mobile: +0086 158 6814 2550

Useful information

- Never Pay before delivery of service, not even for delivery

- Avoid scams by acting locally

- Never pay with Western Union, Moneygram or other anonymous payment services

- Meet in an open an public place like resturant

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"

Loading

Loading