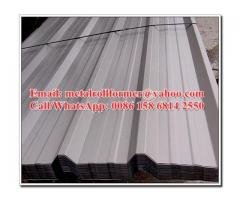

Galvalume Metal Roof Panel Roll Forming Machine , R Panel Cold Roll Forming Equipment

Published date: July 20, 2017

Nigeria, Hangzhou, Xiaoshan

Metalrollformer@yahoo.com

Views: 428

Check with seller

008615868142550

Description

Painted and Galvalume Metal R Roof Panel Rollformer with Mitsubishi PLC Operator and Automatic Decoiler

Information of R roofing panel roof sheets made by metal roll former

1. 36" coverage with 1 1/4" high ribs

2. Panel lengths up to 42 feet are available

3. R Panel available in 22, 24, 26, and 29 gauge

4. Available Finishes Painted, Zincalume, Galvalume, A606 ( Corten ), Bare Cold Rolled, Bonderized

5. PBR panel is available in a wide variety of finishes and colors in 24, 26, or 29 guage

6. R Panel is great for self storage, commercial / industrial roof and wall applications, equipment screens, agricultural and residential construction.

7. Matching Zincalume, Galvalume, Galvanized or pre-painted finishes are available for flashings and flat stock.

8. Self-sealing fasteners are available for wood or steel applications. Painted or Galvanized.

Galvalume Metal Roof Panel Roll Forming Machine , R Panel Cold Roll Forming Equipment

Main Parameters of Steel R-panel Roof Roll Former

1. Material Spec. Q345 or 34 KSI; Thickness: 0.4mm to 0.7mm

Galvanized Steel Sheets in COILS (ex: JIS 93 302)

Prepainted Galvanized Steel Sheets in COILS (ex: JIS G 3312)

Galvalume Steel (ALUZINC) Simple or Prepainted in COILS

Colored Aluminium Sheets in COILS (ex: AA 5005 & 3003)

2. Hydraulic decoiler Max. Capacity: 5000KGS

3. Controlling system: PLC; Working speed: 18~20m/min

4. Main machine power: 7.5kw; Hydraulic station power: 2.2kw

5. PLC: PLC control panel, transducer and touching screen imported from Mitsubishi

6. Power: 380V/3ph/50HZ or at buyer's requirement.

Working Flow

Active Decoiling → Material Guilding & Feeding → Roll Forming → Cut-to-length → Run out

Galvalume Metal Roof Panel Roll Forming Machine , R Panel Cold Roll Forming Equipment

Main Components of Roll Forming Line

5 Tons Hydraulic Uncoiler 1 set

Direction Guilding Device 1 set

Cold Rollformer System 1 set

Hydraulic Cutting Device 1 set

Mitsubishi PLC Control System 1 set

Runout Tables 1 set

Tools Box 1 set

Application

R Panel is the nicest panel for the least amount of money. This metal roofing panel provides more of a contemporary look for someone that does not want a wavy corrugated panel.

We are supplying all kinds of oven baked aluminium roofing sheets making machines, such as box prfiled longspan metral roofing sheet corrugating machine, normal steptile roof sheet making machine, metcopo step tile roof sheet corrugation machine, cameroon aluzinc roof sheet making machine, ridge cap manufacturing machine and so on. If you want to get more details about this Customized Long Span Aluminium Roof Panel Roll Forming Machine with High Working Speed, please contact us by the following information!

Email: metalrollformer@yahoo.com

Mobile: +0086 158 6814 2550

Useful information

- Never Pay before delivery of service, not even for delivery

- Avoid scams by acting locally

- Never pay with Western Union, Moneygram or other anonymous payment services

- Meet in an open an public place like resturant

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"

Loading

Loading